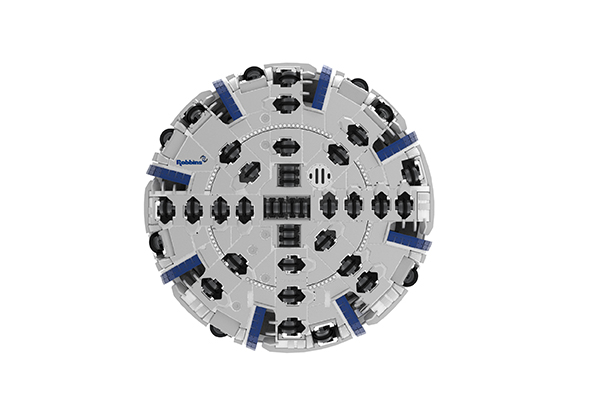

The TBM Cutter Ring is a very important component used in modern tunnel boring machines. It is used to cut and grind rock and soil from the tunnel walls, converting it into easily removable fragments. The manufacturing process of TBM Cutter Ring is very complicated and needs to go through multiple process steps to ensure its stable and efficient operation.

In general, the manufacture of TBM Cutter Ring requires the following process steps:

1. Material selection: TBM Cutter Ring is usually made of alloy steel and carbon steel to ensure it has sufficient strength and hardness. In terms of material selection, manufacturers need to consider factors such as geological conditions and the diameter of the tunnel.

2. Making knives: The knives for making TBM Cutter Ring need to cut out the arc shape accurately. During this process, manufacturers need to use advanced machines and technologies to ensure the precision and quality of the knives.

3. Cutting and processing: The finished knives will be used to cut and process TBM Cutter Ring. This process requires the use of a variety of equipment and techniques, such as milling, drilling, wire cutting and diamond grinding.

4. Inspection and testing: A well-manufactured TBM Cutter Ring requires several inspections and tests to ensure its quality and performance meet the requirements. Test items include hardness, strength, roundness, etc., as well as on-site trial operation.

Generally speaking, TBM Cutter Ring is one of the core components of TBM roadheader. The process of manufacturing TBM Cutter Ring requires precise technology and strict quality control to ensure that it can operate stably and efficiently, providing effective support for tunneling work.