In modern underground engineering, TBM (Tunnel Boring Machine) plays a vital role, and its core component – TBM cutting head is known as the main force of underground engineering. The TBM cutting head is responsible for cutting underground rock and soil through powerful cutting and extrusion, providing a solid foundation for stable and safe tunneling.

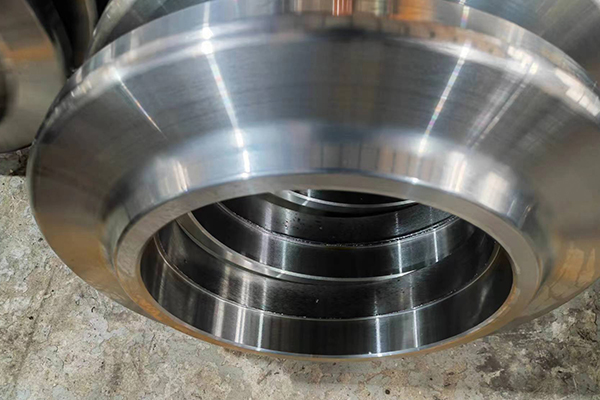

The TBM cutting head consists of multi-layer cutters, usually made of cemented carbide to ensure high strength and wear resistance in harsh underground environments. Mounted on the outer edge of the cutting head disc, these knives rotate and continuously cut through subsurface rock and soil during mechanical advance.

TBM cutting heads are designed to suit different geological conditions and tunnel needs. There are different types of cutting heads available such as open disc cutting heads and closed cutting heads. Open-disc cutting heads are suitable for stable geological conditions, and they have a more open cutter arrangement, which can effectively clean up cutting products. Closed cutting heads are suitable for unstable geological conditions, and their cutter layout is more compact to prevent rock collapse and soil influx.

The function of TBM cutting head in underground engineering is not only cutting and extrusion. They also control deformation and caving of rock formations, maintaining the stability of the tunnel. Some advanced TBM cutting heads are also equipped with sensors and instruments that can monitor the conditions of the underground rock and soil in real time, as well as the working status of the cutting head. This enables operators to make timely adjustments and decisions to ensure safe tunneling.

As technology continues to advance, so does the performance of TBM cutting heads. Some of the latest cutting heads use advanced hydraulic and electric control systems to achieve higher cutting efficiency and more precise control capabilities. In addition, some cutting heads also have automatic functions, which can automatically adjust the angle and speed of the tool according to different geological conditions, improve work efficiency and reduce the risk of human operation.