Product

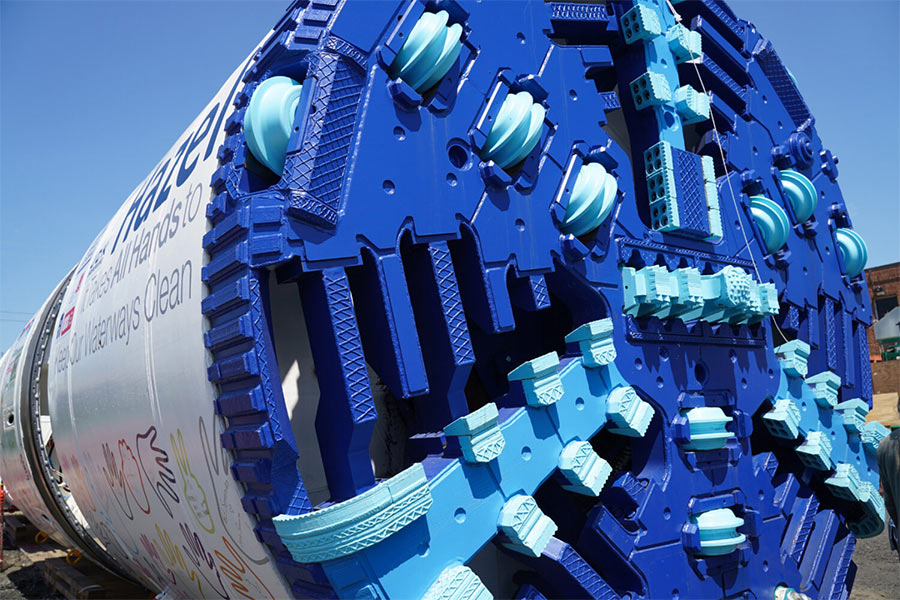

TBM Cutter Ring

The main product materials are: die steel H13ESR, DC53 is suitable for hard rock disc cutters of tunnel shield machines, LD is used; cold work die steel Cr12, Cr12Mov, Cr12Mo1V, Cr12Mo1V1 is suitable for cold punching, extrusion, and rolling molds Etc.; stainless iron 1-4Cr13 is suitable for valves, plastic molds, etc.

Description

TBM disc cutter is a disc-shaped roller cutter mounted on the cutterhead of tunnel boring machine, which is an excavation tool for breaking hard rocks. The type of disc cutters, in different sizes and specifications, can be mounted on the cutter heads of large trenchless construction equipment such as TBMs, shield machines, MTBMs, pipe jacking machines, shaft boring extension machines, and are widely used in subway tunnels, railway tunnels, diversion tunnels, urban underground pipe network construction, mining and other industries.

| No. | Rock Yield Strength | Disk beat | Material | Ingredient list | Hardness | Description of the scope of application |

| 1 | >50Mpa | Hard rock special steel disk beat (Gradient hardness from ring to edge to ensure higher impact toughness and longer life) | H13E US Grade | C 0.47-0.52 Si 0.9-1.2 Mn 0.4-0.6 Cr 4.8-5.2 Mo 1.1-1.4 V 0.8-1.0 P 0.015 S 0.015 | HRC56-59 | Conventional disk beat, the normal use range is within 100 MPa, and the scrap rate is extremely high after exceeding |

| 2 | 8418 Sweden Grade | C 0.65-0.75 Si 0.2-0.5 Mn 0.4-0.6 Cr 5.0-6.0 Mo 2.2-2.4 V 0.5-0.7 P 0.015 S 0.015 | HRC58-60 | High toughness and wear-resistant type, suitable for uneven soft and hard rock formation, anti-collapsing angle and anti-fracture | ||

| 3 | 2367 Germany Grade | C 0.54-0.57 Si 0.3-0.5 Mn 0.3-0.5 Cr 4.5-5.5 Mo 2.9-3.1 V 0.5-0.7 Nb 0.1-0.15 P 0.015 S 0.015 | HRC58-60 | Enhanced version of 8418, mainly to improve toughness and strength, more suitable for complex rock formations, wear resistance close to 8418 | ||

| 4 | DC53 Japan Grade | C 0.9-1.1 Si 0.9-1.2 Mn 0.2-0.4 Cr 7.5-8.5 Mo 1.8-2.2 V 0.3-0.5 P 0.015 S 0.015 | HRC60-63 | Extremely wear-resistant and high-hardness cutter ring, suitable for full-section rock formation with yield strength tolerance <10Mpa | ||

| 5 | LD Invented by Shanghai Metallurgical Institute | C 0.68-0.78 Si 0.9-1.2 Mn 0.2-0.4 Cr 6.5-7.5 Mo 1.8-2.2 V 1.7-2.2 P 0.015 S 0.015 | HRC62-66 | Enhanced version of DC53, with higher toughness and hardness, suitable for full-section rock formations that DC53 cannot satisfy | ||

| Note: Soft and hard uneven complex rock formations (used by 8418 and 2367) and full-section rock formations with a strength of plus or minus 5 MPa (used by DC53 and LD) | ||||||

Application

Video

Play Video

Play Video

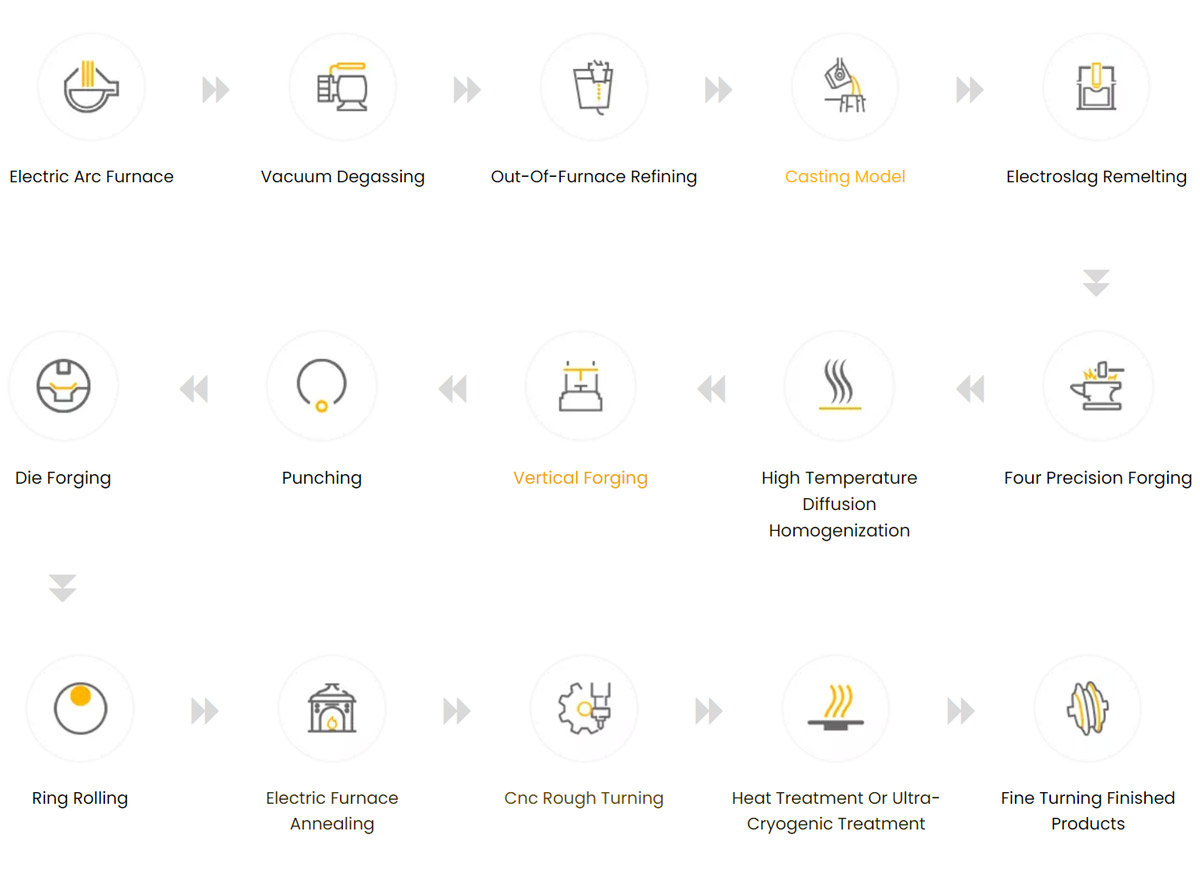

Process