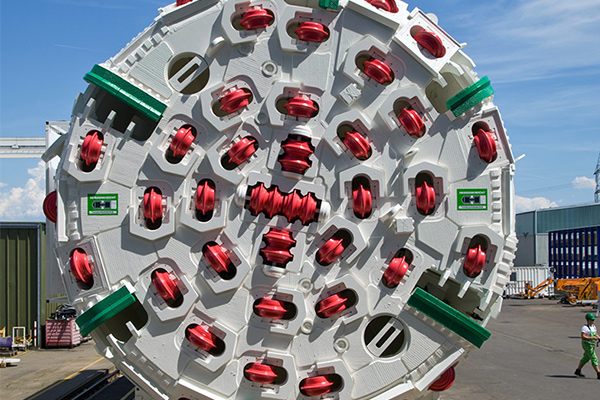

Tunnel boring machines, also known as TBMs, are pieces of equipment primarily used for excavation projects. Of these machines, the cutter head TBM is particularly useful for excavating tunnels in strong, durable rock and soil formations. Configured to contain a rotating disc–shaped cutting head that slices through material, this type of TBM has been a crucial asset for engineers since the 1960s. Thanks to its advancements in technology and versatilities, cutter head TBM has become the primary equipment used in engineering projects around the world such as, bridges and canals.

Cutter head TBMs contain a number of advantages compared to other TBMs. Its rotating cutter head is highly hydraulically powered, allowing it to effortlessly cut through tough materials such as basalt, granite or sandstone. It is reliable and efficient, with automated excavation capabilities which makes it less labour intensive. These machines can also be equipped with steerable and keyhole cutters that give operators the freedom to excavate to their exact needs. Furthermore, modern cutter head TBMs also come with features that increase overall safety and quality of work. Real–time monitoring systems keep a check on all the components and can give alarm in case of any potential risk. Cutters and disc inserts are replaced with ease and can be changed to cater to specific materials. Smart sensors and on–board computer systems are also available that can identify and rectify any deviation to ensure that a tunnel is created according to the engineers’ exact specifications.

Whether the project is a bridge, highway, canal or other infrastructure, cutter head TBM is the go–to engineering solution. This technology ensures greater accuracy, quality, safety and efficiency along with being environmentally friendly. Thanks to these attributes, this revolutionary cutting technology has revolutionized civil and mining engineering, making the seemingly impossible possible.